Case studies

Customer satifaction is our priority! See what our customers say about us.

Case study

Pharma / OTC

A smart solution for filling THC oil for pharmaceutical purposes

The challenge: precision, hygiene, and flexibility.

Case study

Food & Drinks

Automation and quality for oil filling

A compact, flexible, and hygienic line ensuring precision and efficiency for multiple bottle formats

Case study

Chemicals

Automation and precision for automotive oil packaging

Delivering high-speed, accurate, and flexible packaging across multiple bottle formats with a fully integrated modular solution

Customers & partners

Inspiring students to connect STEM skills with real-world industrial applications

Case study

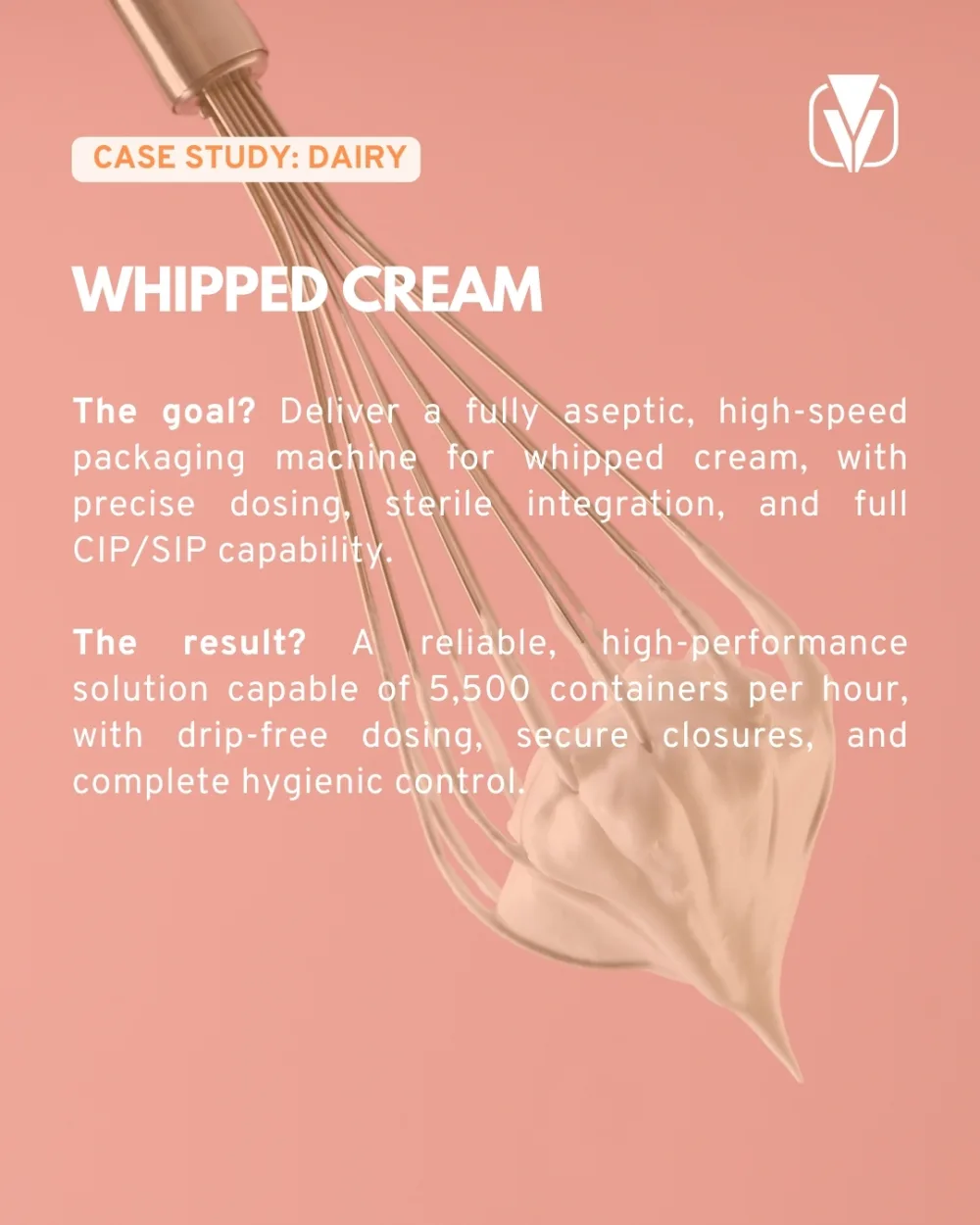

Dairy

Custom aseptic solution for high-sensitivity whipped product packaging

Delivering precision, hygiene, and efficiency for sensitive food applications

Case study

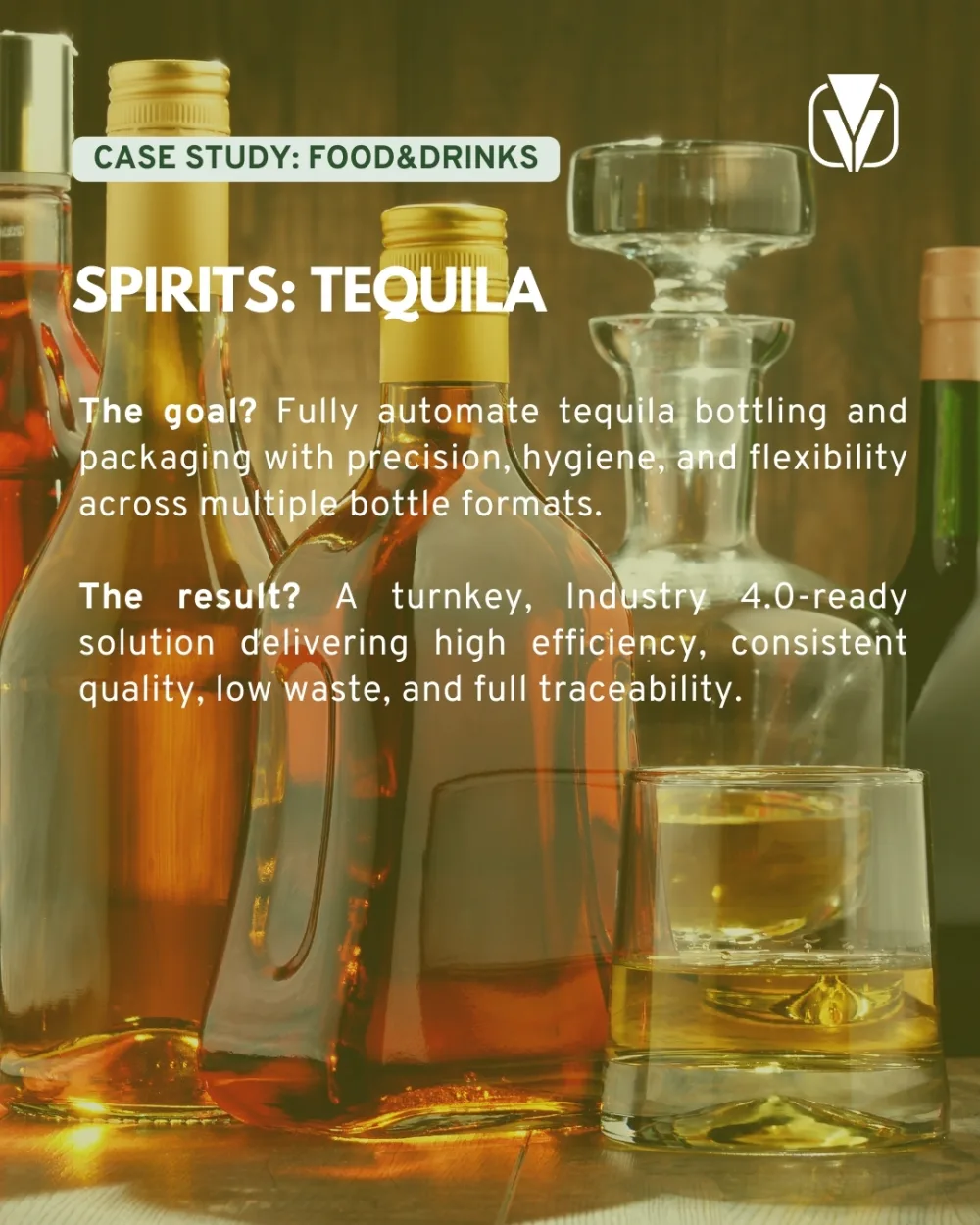

Food & Drinks

Seamless automation for tequila packaging

Achieving unmatched precision, hygiene, and efficiency across multiple bottle formats with a fully integrated, Industry 4.0-ready packaging solution

WEIGHTPACK SRL

Strada Bardelletta 10/b

46044

Goito, Mantova - Italy

P.IVA 01974940205

weightpack@legalmail.it

Contacts

Phone

+39 0376 689255

E-mail

Sales

Support

Purchase

Newsletter

Are you ready for Lubricant Expo NA?✨

Join us from Mar 17 to Mar 19 at Booth 504.📌