Unequaled filling accuracy

The constant tare and net weight tolerance controls, the self learning and continuous adaptation to changing conditions and the scale reset at each machine revolution allow our machinery to reach a standard deviation of σ < 1g and mean at setpoint ± 0,5g.

Fail-proof features

After numerous checks, should a breakdown occur, machine features can be activated to continue operating safely. In the event that the machine does not detect the presence of bottles, the filling phase will not begin. In case there are problems on only one filling station, the latter can be excluded.

Features and Specifications

Plunger valves

- Drip-proof

- Splash-free

- No strings

- No tails

- Foam retarding

- Shoulder fill / even surface

- Oxygen abatement (patented)

- Pneumatic piston

- Pneumatic-magnetic

- Solenoid

- Multistage

- Flexible membrane

- Scraper / wiper

- Floating plunger (seal-free)

Filling technology

- Gravimetric (tank on-board)

- Volumetric (tankless)

- Neck handling

- Body handling

- Auger

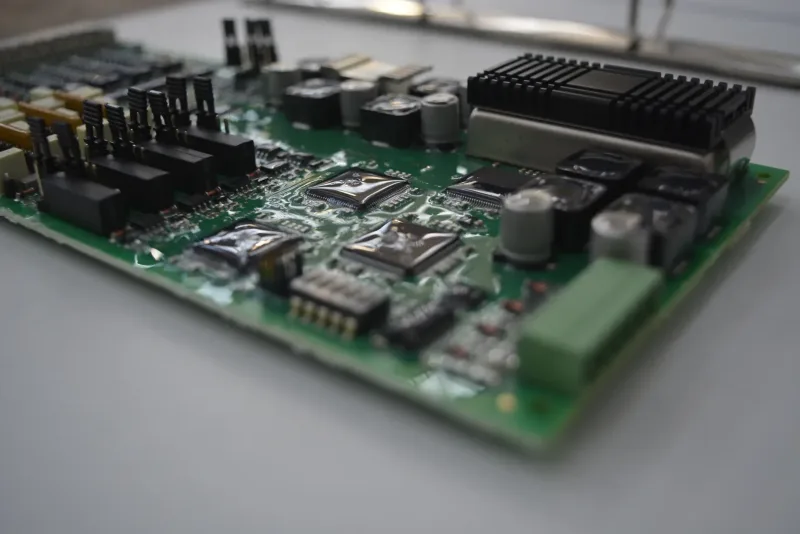

Behind the scenes

Our solutions can treat all kinds of viscosities in glass, cans, plastics and others, from edible oils to peanut butter and are designed specifically for each customer.

P.IVA 01974940205

weightpack@legalmail.it

Join us from Mar 17 to Mar 19 at Booth 504.📌