Case studies

Customer satifaction is our priority! See what our customers say about us.

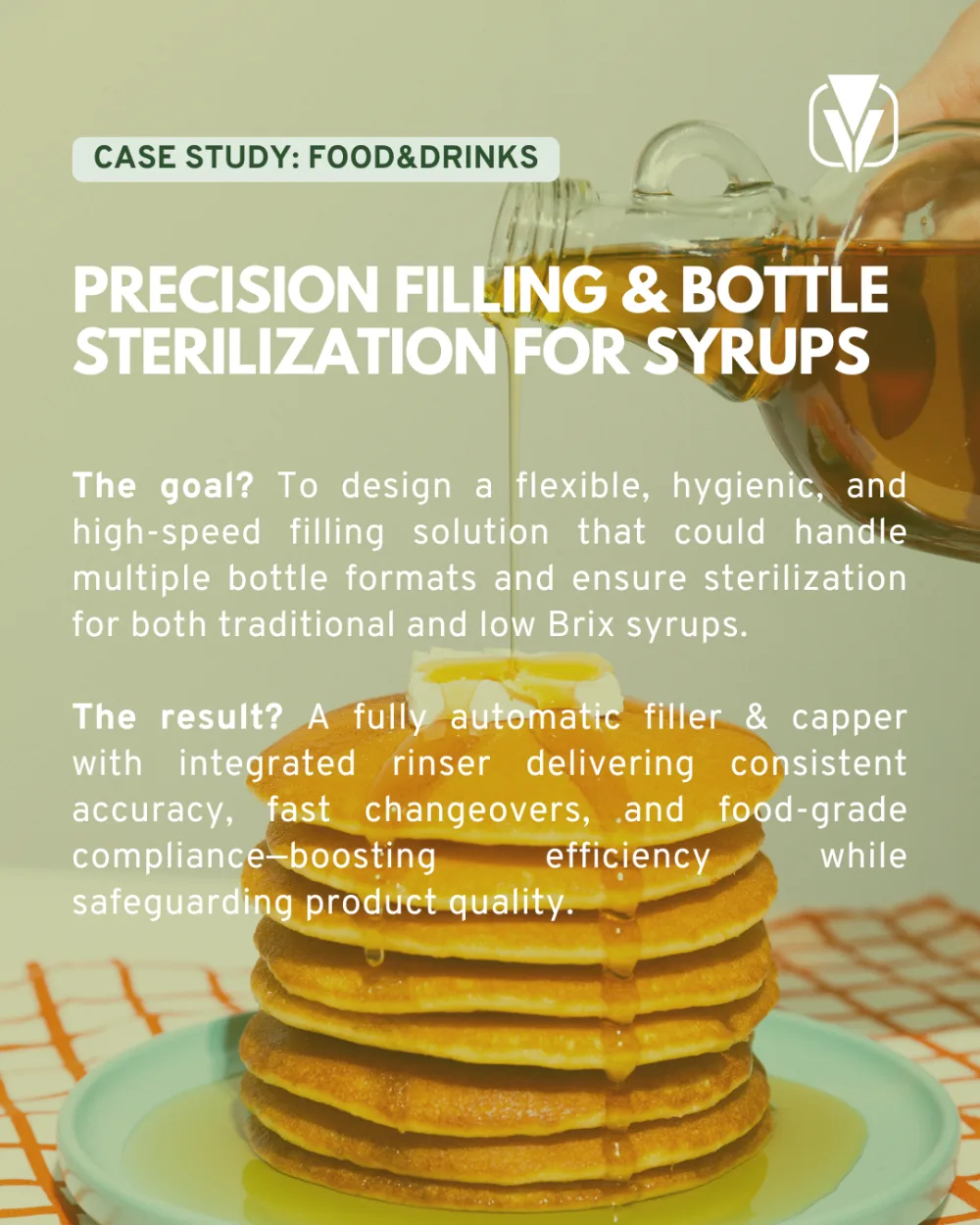

The challenge: precision, hygiene, and flexibility.

A compact, flexible, and hygienic line ensuring precision and efficiency for multiple bottle formats

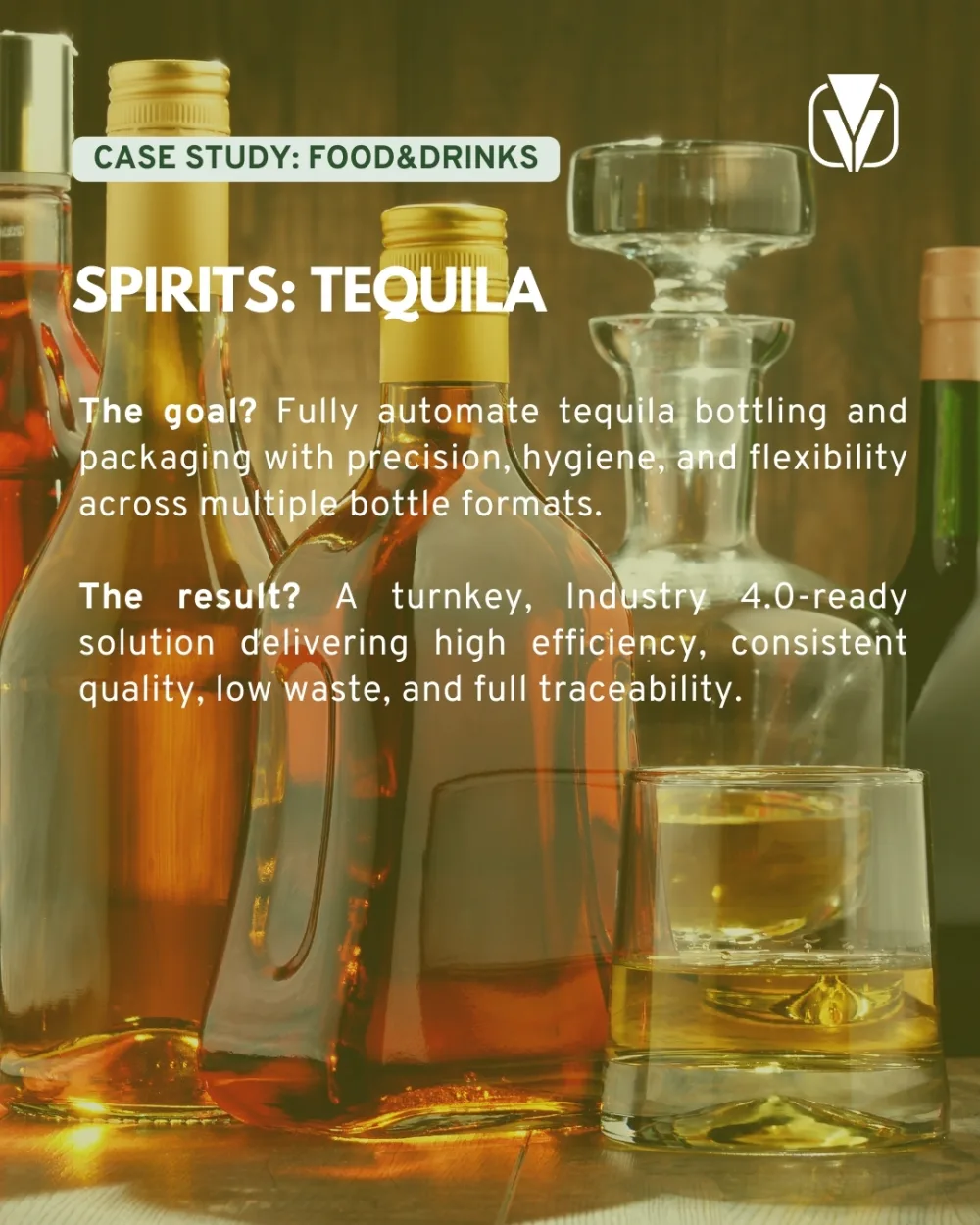

Delivering high-speed, accurate, and flexible packaging across multiple bottle formats with a fully integrated modular solution

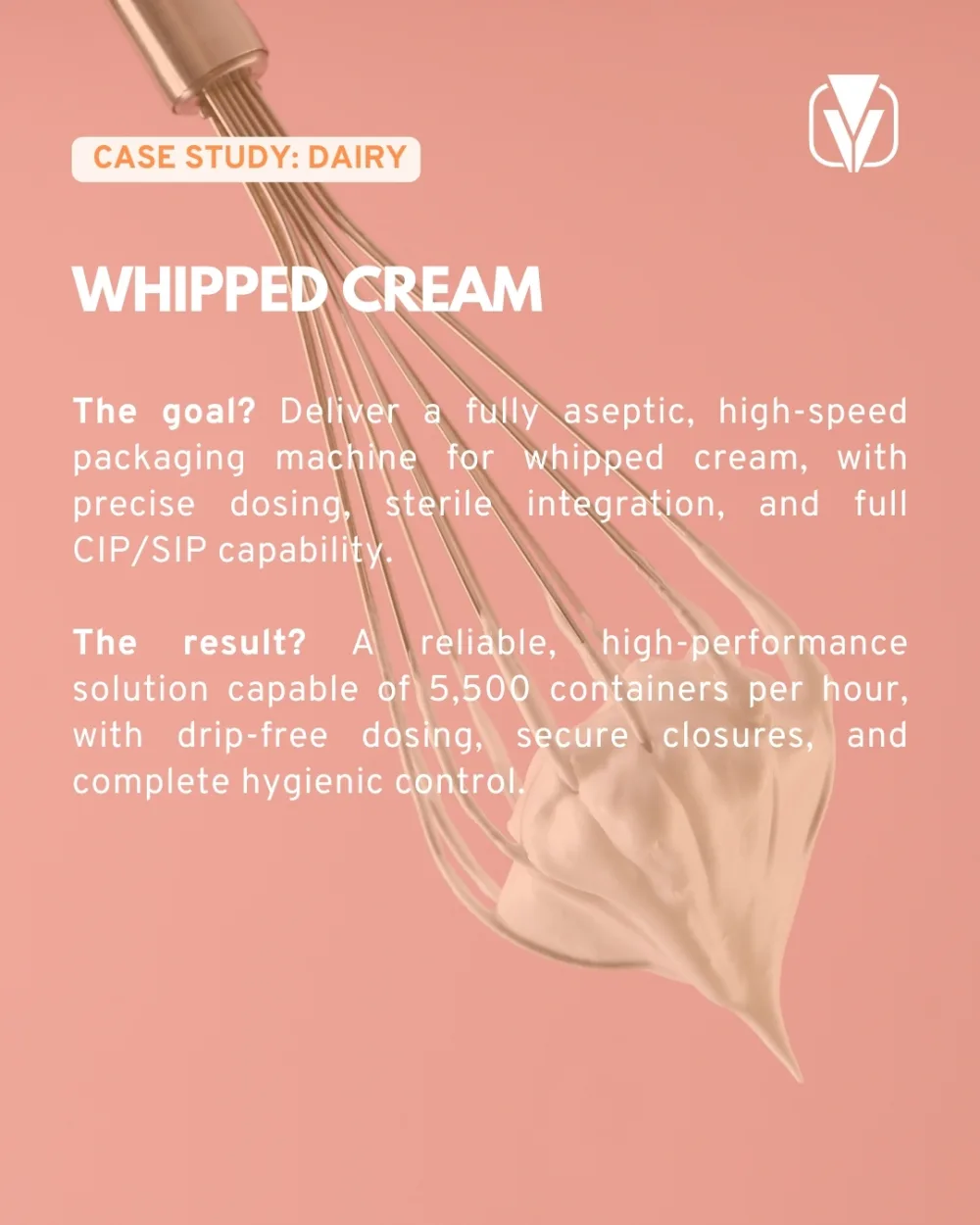

Delivering precision, hygiene, and efficiency for sensitive food applications

Achieving unmatched precision, hygiene, and efficiency across multiple bottle formats with a fully integrated, Industry 4.0-ready packaging solution

Syrup filling is about more than speed—it’s about precision, hygiene, and adaptability. Our net weight fillers with integrated rinsing safeguard product quality by sterilizing containers before filling. The outcome: reliable performance, effortless changeovers, and maximum production efficiency.

P.IVA 01974940205

weightpack@legalmail.it