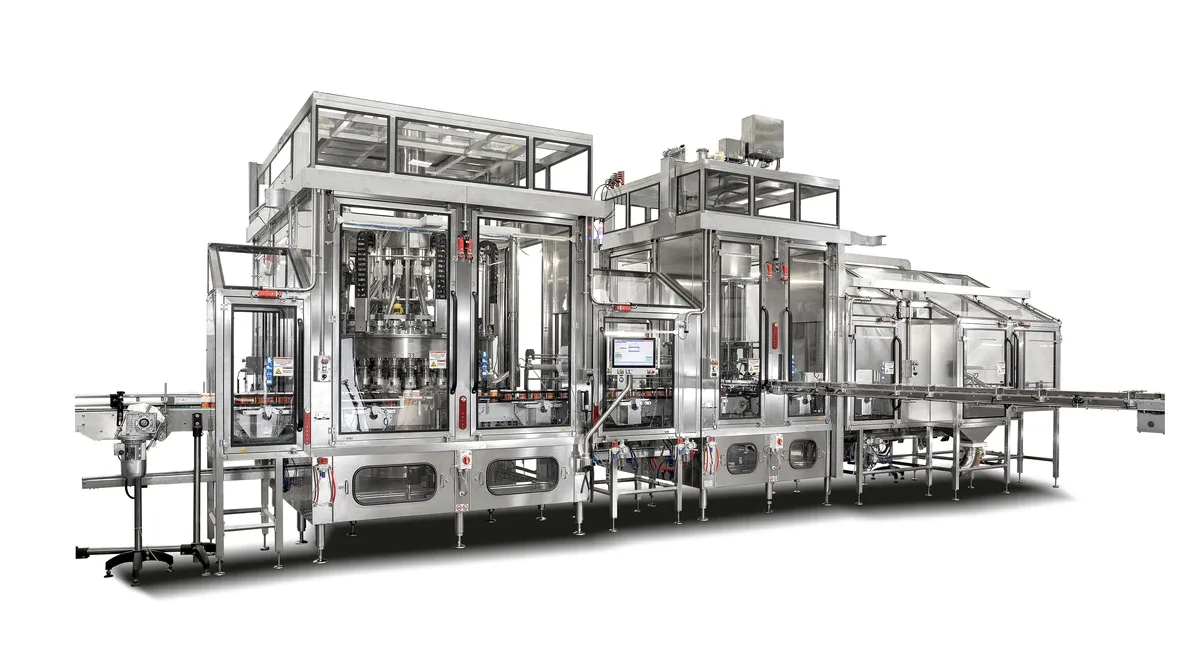

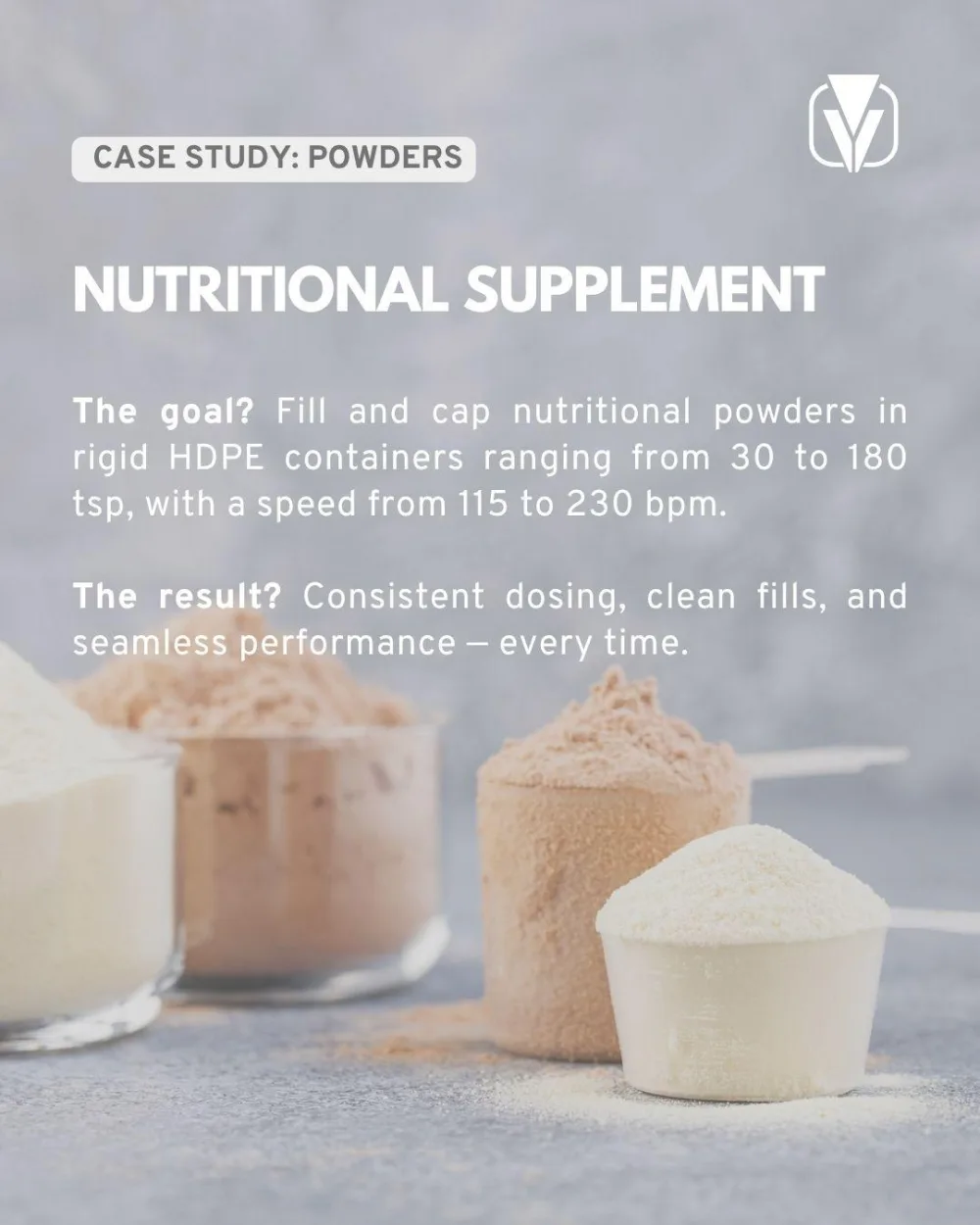

Finest quality of dry, fine-grained substances

Neutraceuticals, sweeteners, coffees and drinks, even cleaning agents and fertilizers.

Just add water or sprinkle directly for desired effects, such as cleaning, beauty enhancement, cooking or enhancing health. Keeping them smoothly flowing is our challenge.

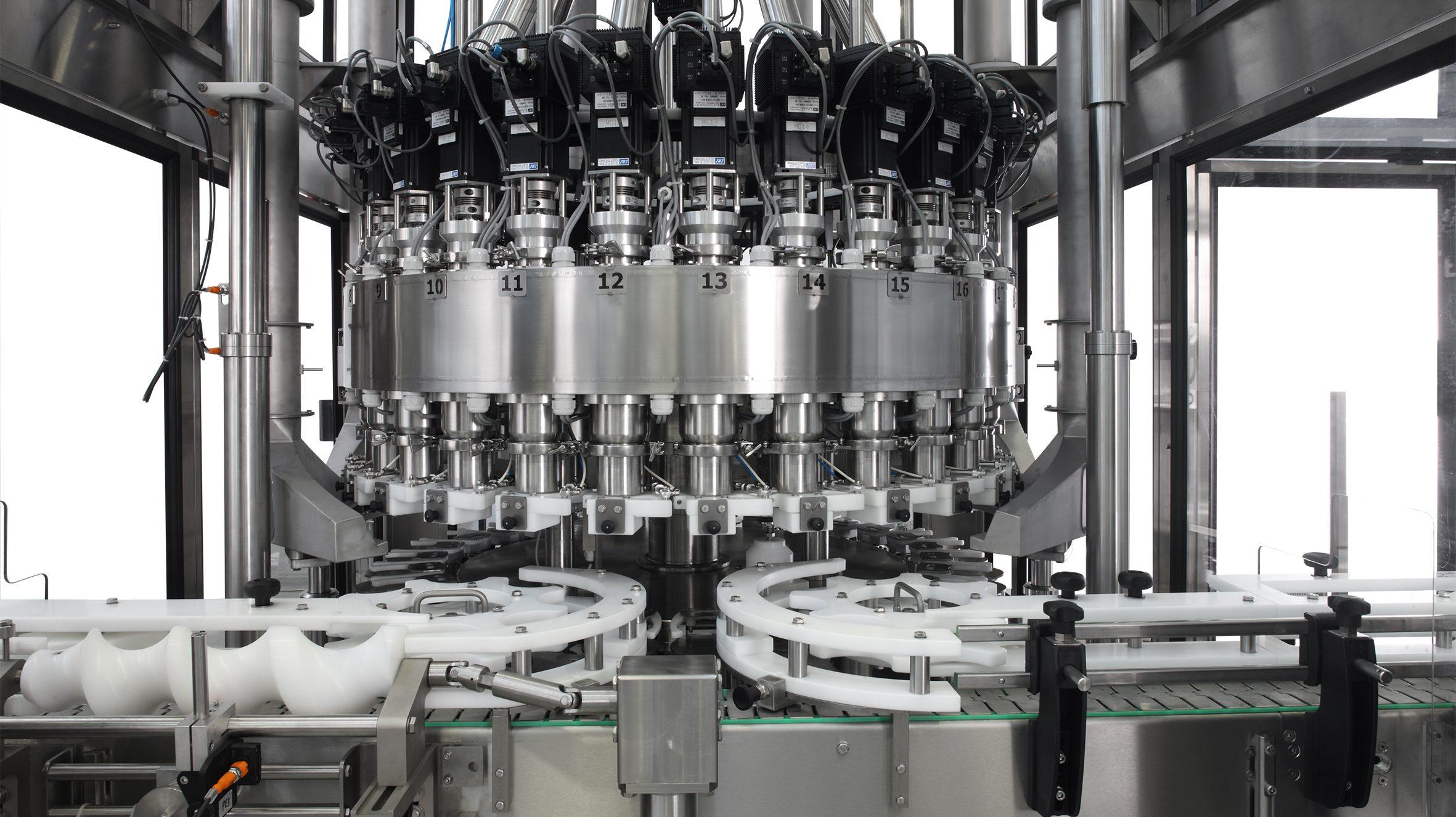

Net Weight Filling Technology

Dedicated closed-loop dynamic weighing, analysis and feed control. The constant tare and Net Weight tolerance controls, the self learning and continuous adaptation to changing conditions and the scale reset at each machine revolution allow our machinery to reach a standard deviation of σ < 1g and mean at setpoint ± 0,5g.

Capping options

Screw cap

Oriented press-on

ROPP

Flip-top

Shrink capsule

Welded foil