Healthy heart, muscles, and bones.

Milk and its myriad fresh, fermented and aged creations are lifelong companions contributing to a long and active life.

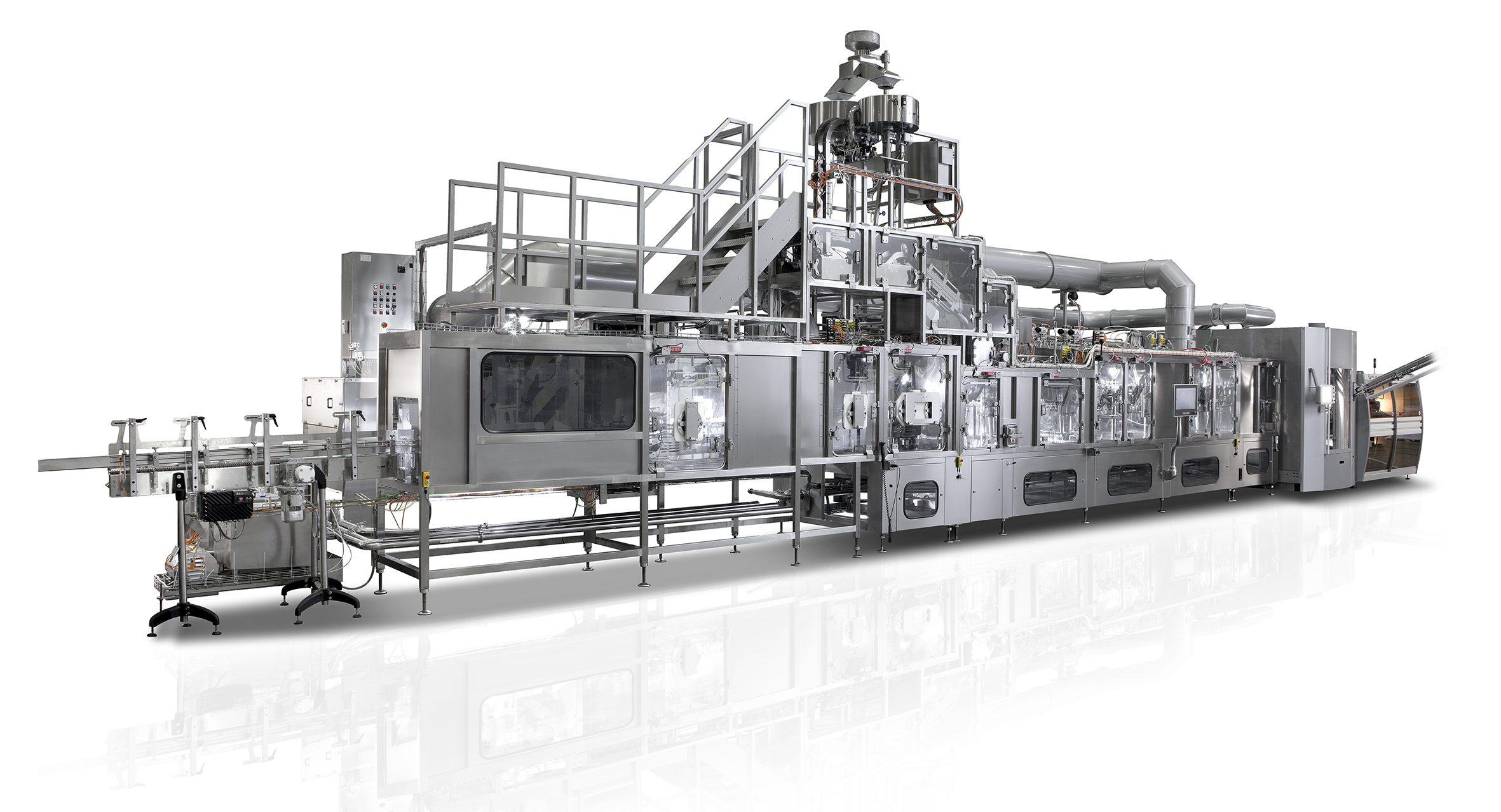

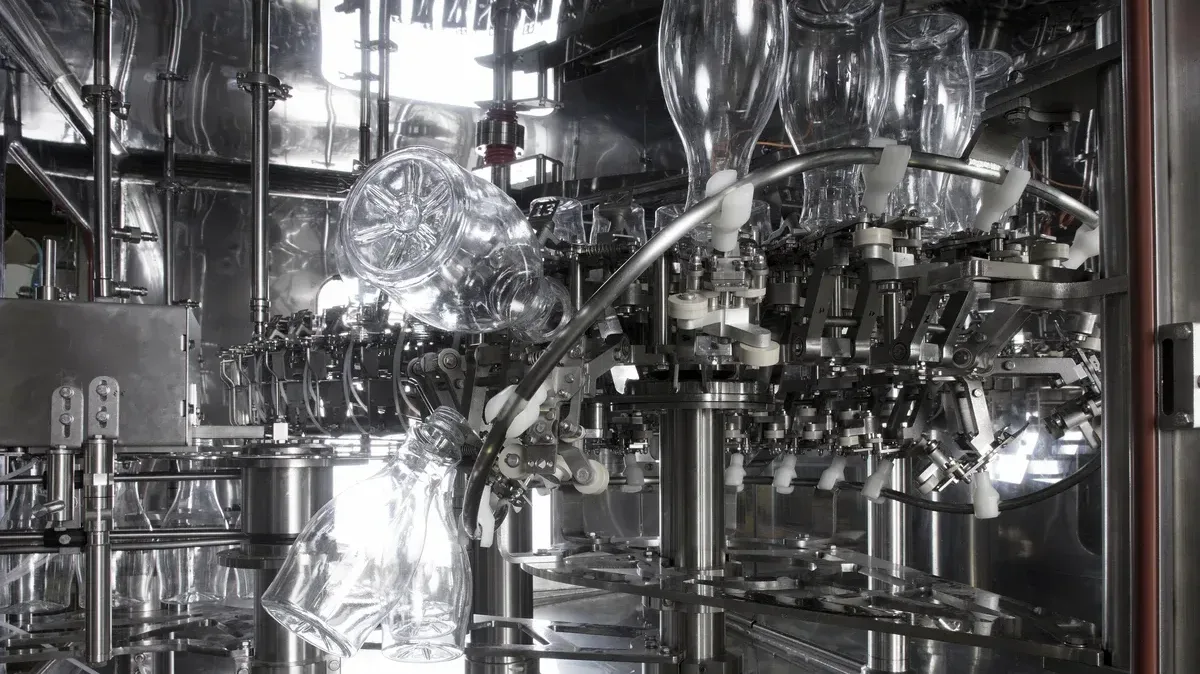

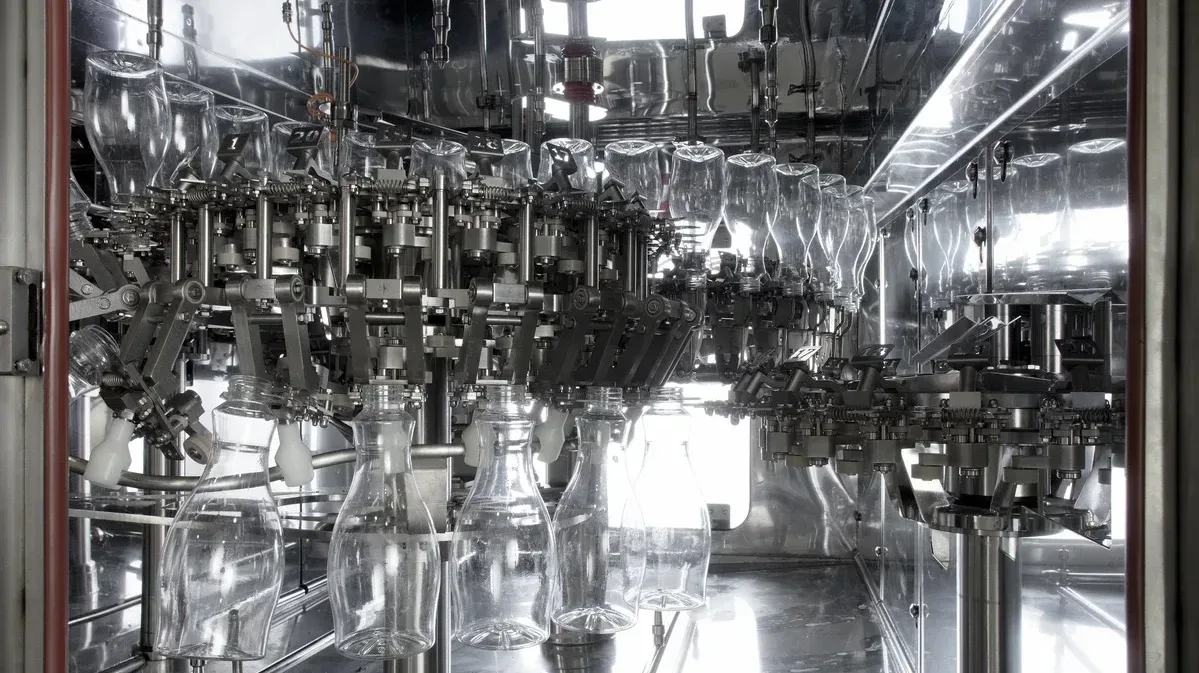

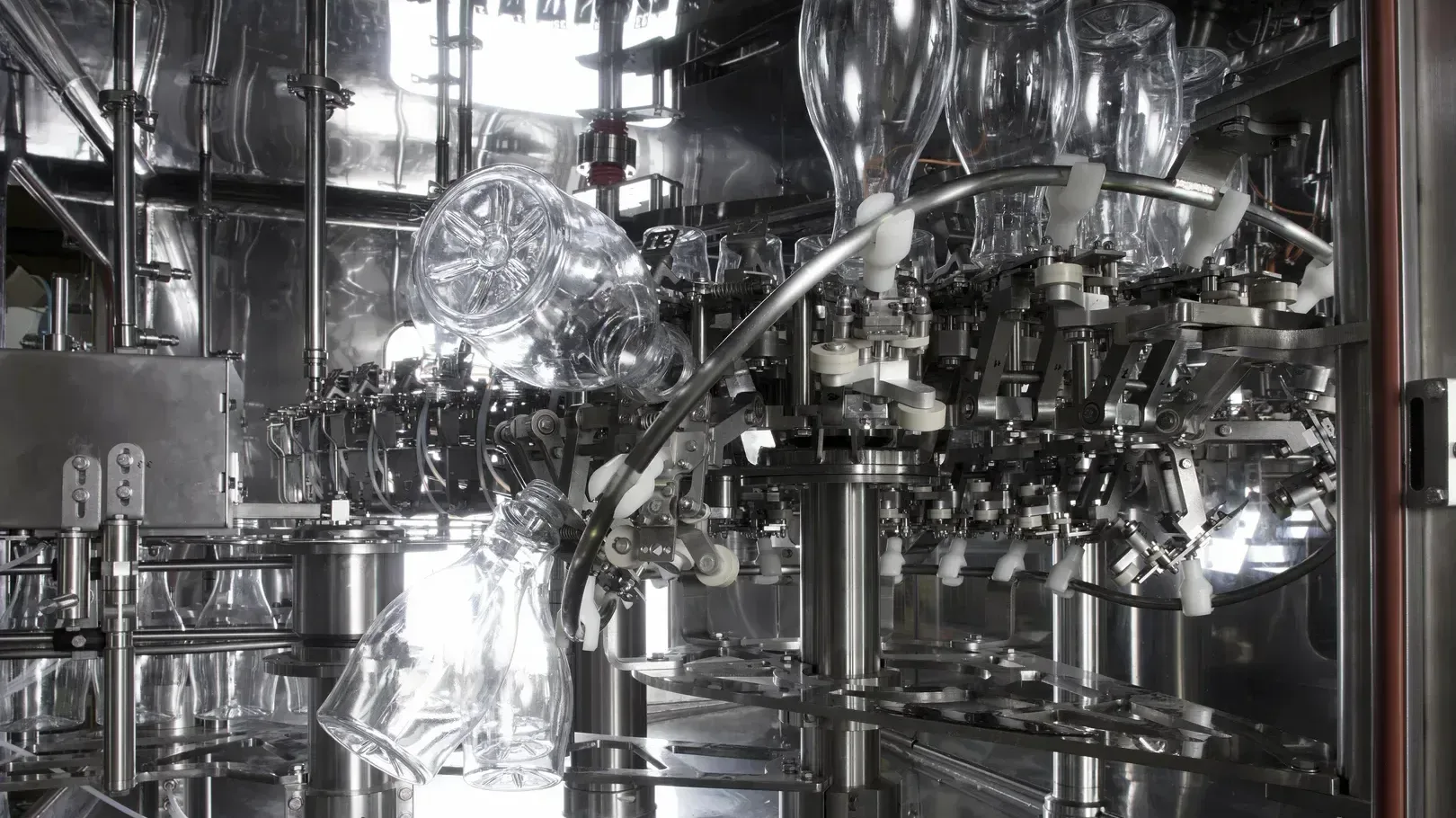

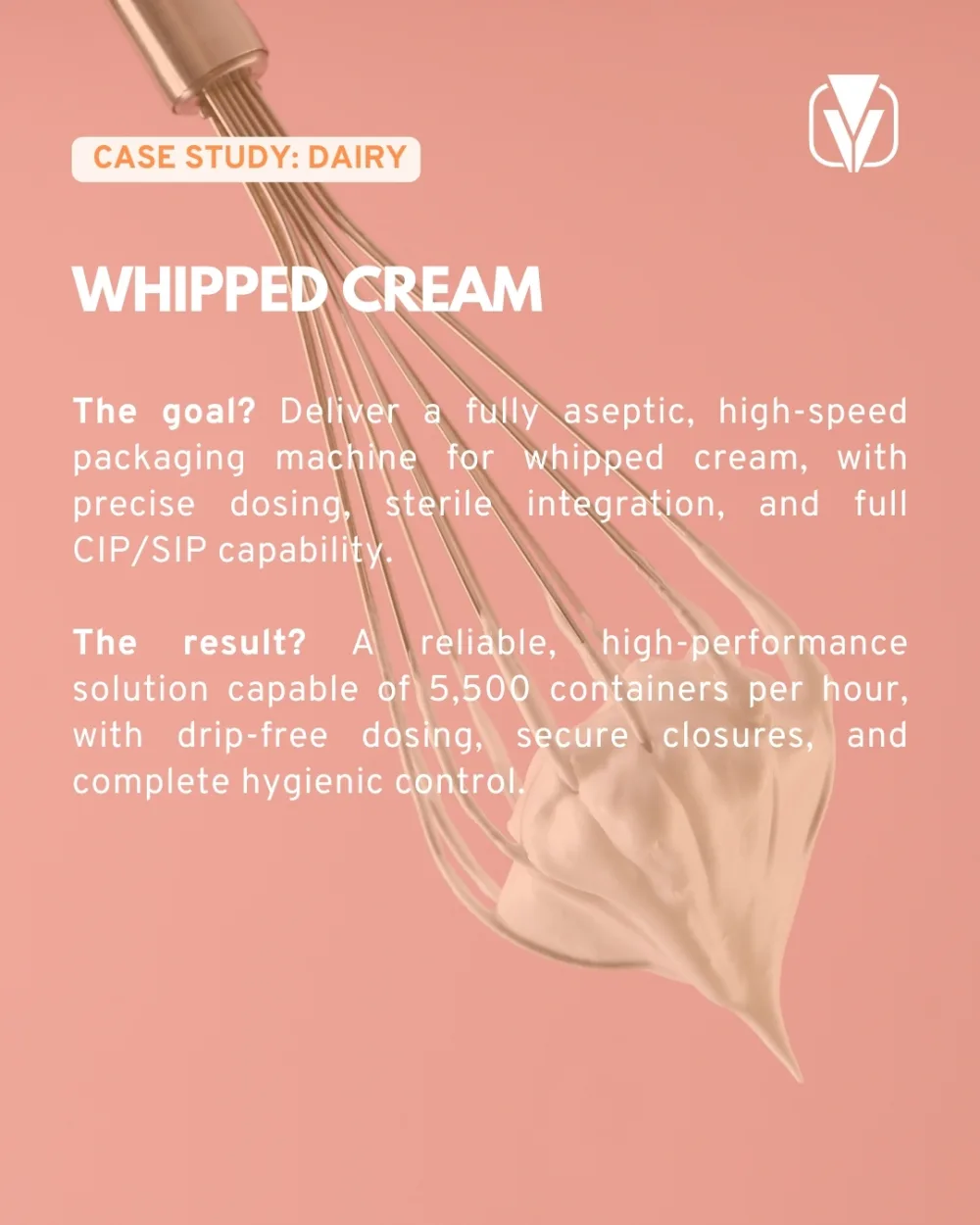

The complex process of keeping our sensitive foods safe from the cow to the consumer requires layers of hygiene control throughout their preparation and distribution.

Powders

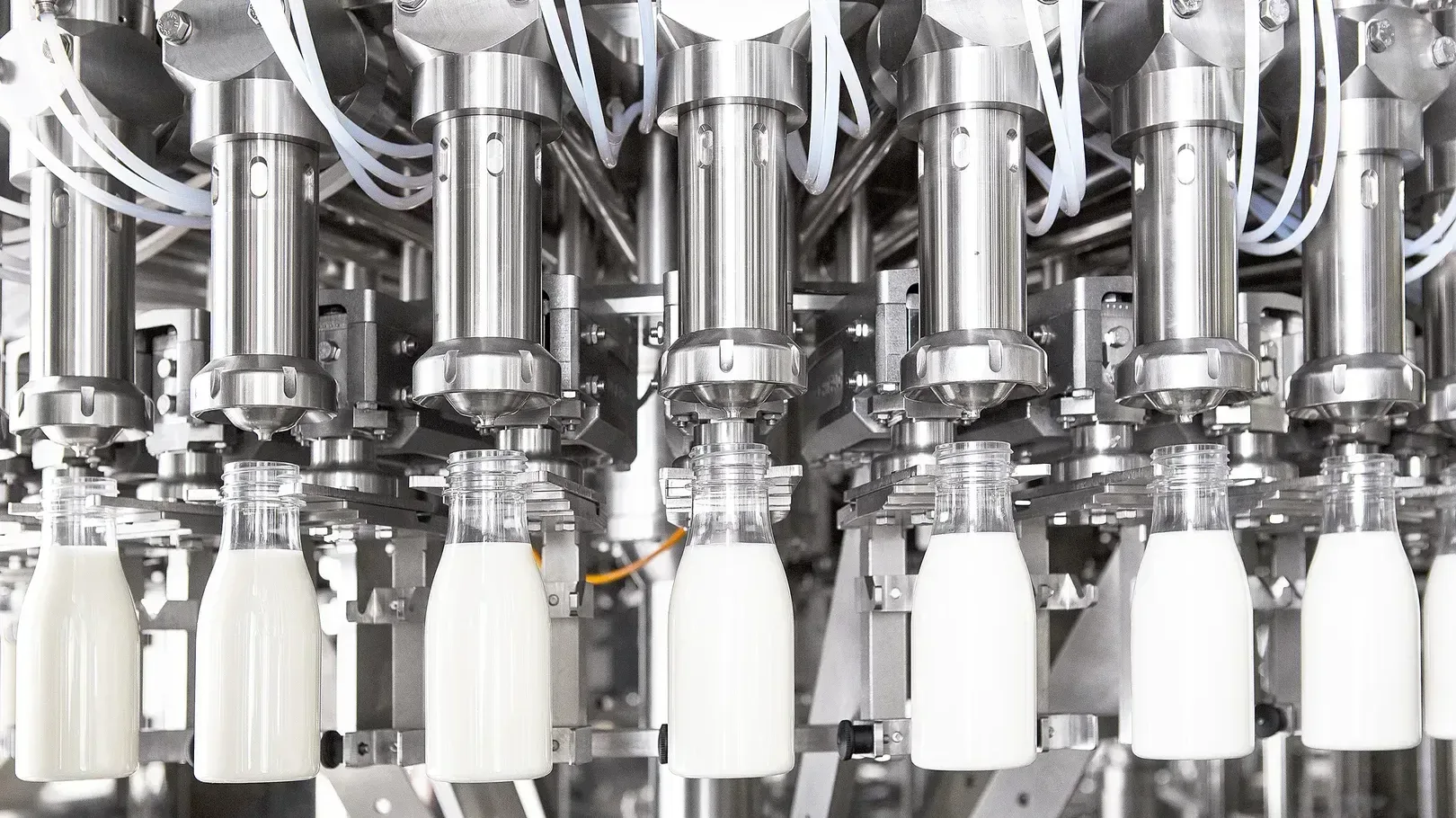

Liquids

Aerosol

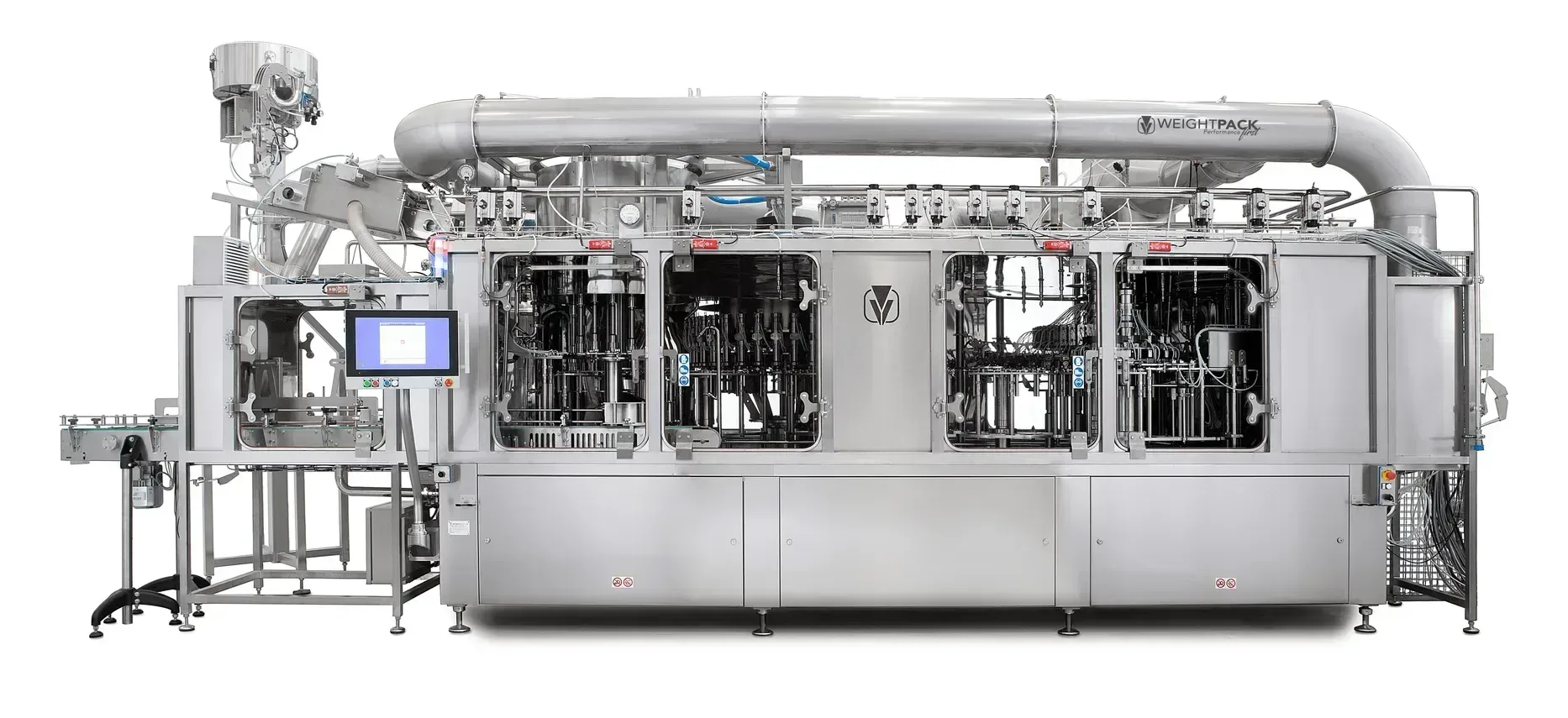

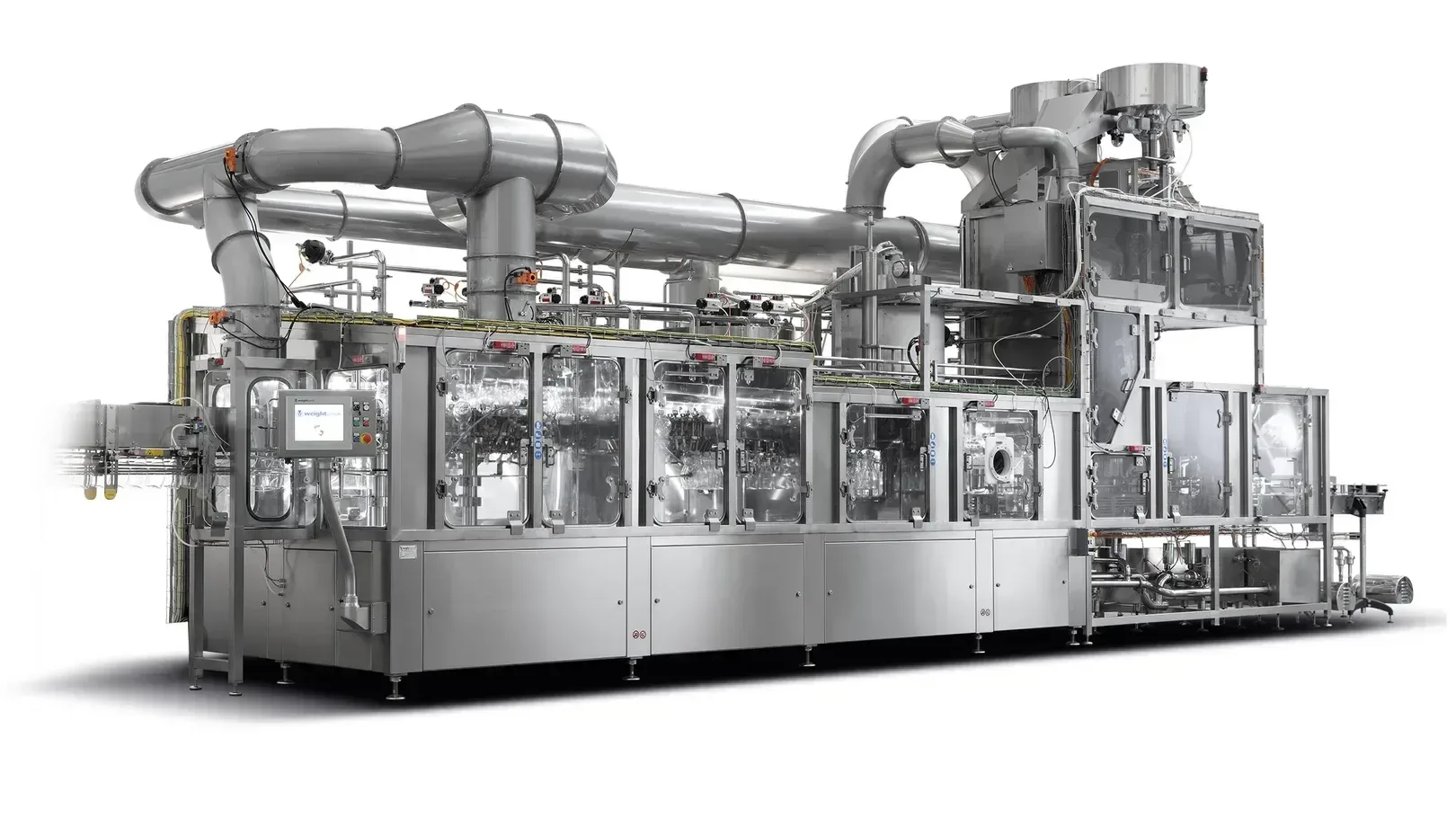

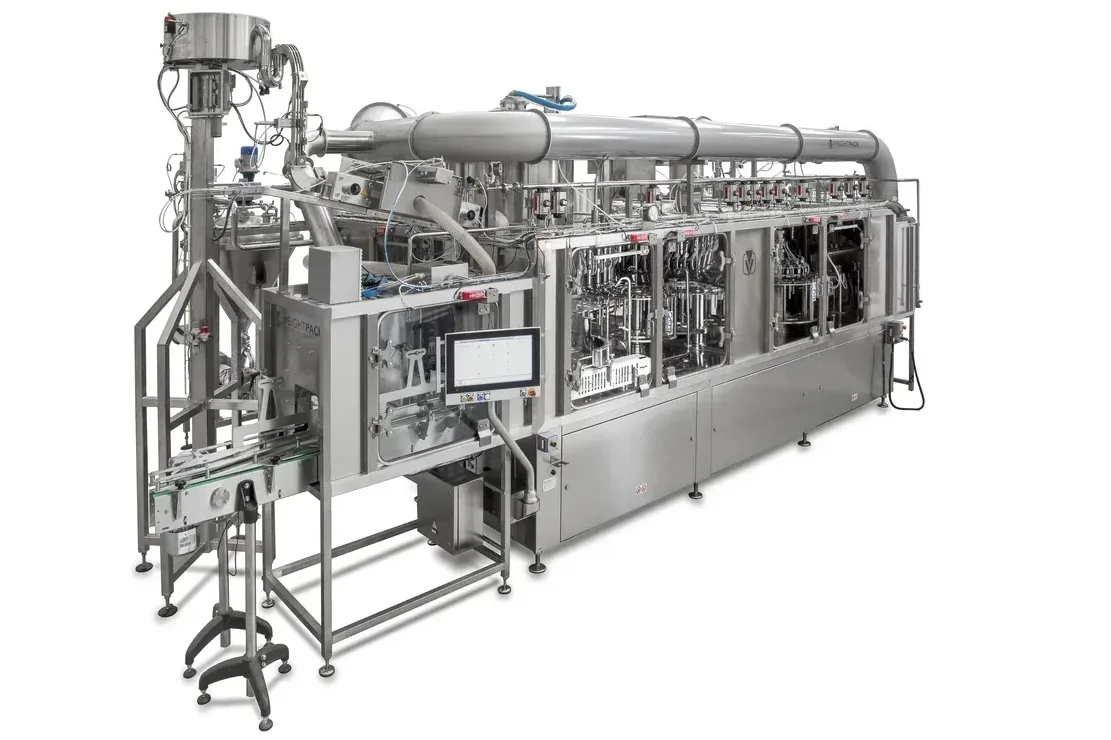

Performance first

Net weight filling technology

Dedicated closed-loop dynamic weighing, analysis and feed control. The constant tare and net weight tolerance controls, the self learning and continuous adaptation to changing conditions and the scale reset at each machine revolution allow our machinery to reach a standard deviation of σ < 1g and mean at setpoint ± 0,5g.

Capping options

Screw cap

Oriented press-on

Crimped aerosol valve

Welded foil