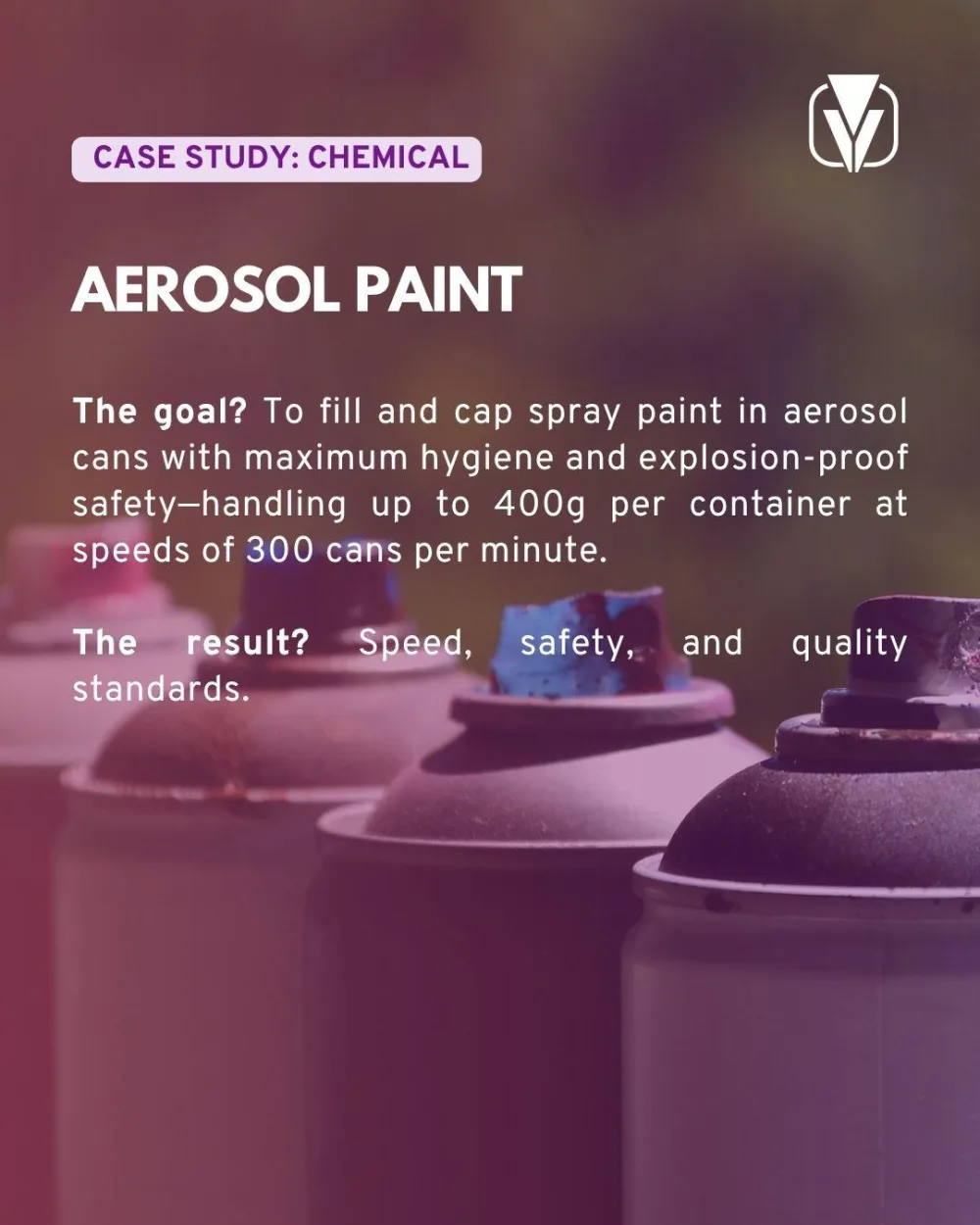

Proper handling of chemicals for better safety in one's life.

Handling high-value chemicals requires special precautions to guarantee a safe working environment.

Highly reactive or explosive liquids for agriculture, automotive, paints and pigments require an emphasis on protections for the workplace.

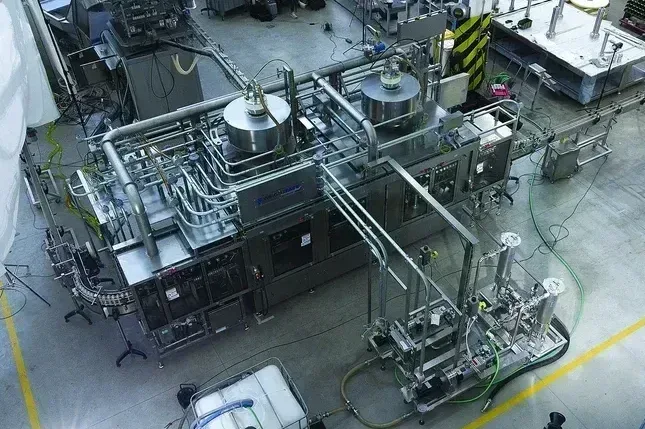

Net Weight Filling Technology

Dedicated closed-loop dynamic weighing, analysis and feed control. The constant tare and Net Weight tolerance controls, the self learning and continuous adaptation to changing conditions and the scale reset at each machine revolution allow our machinery to reach a standard deviation of σ < 1g and mean at setpoint ± 0,5g.

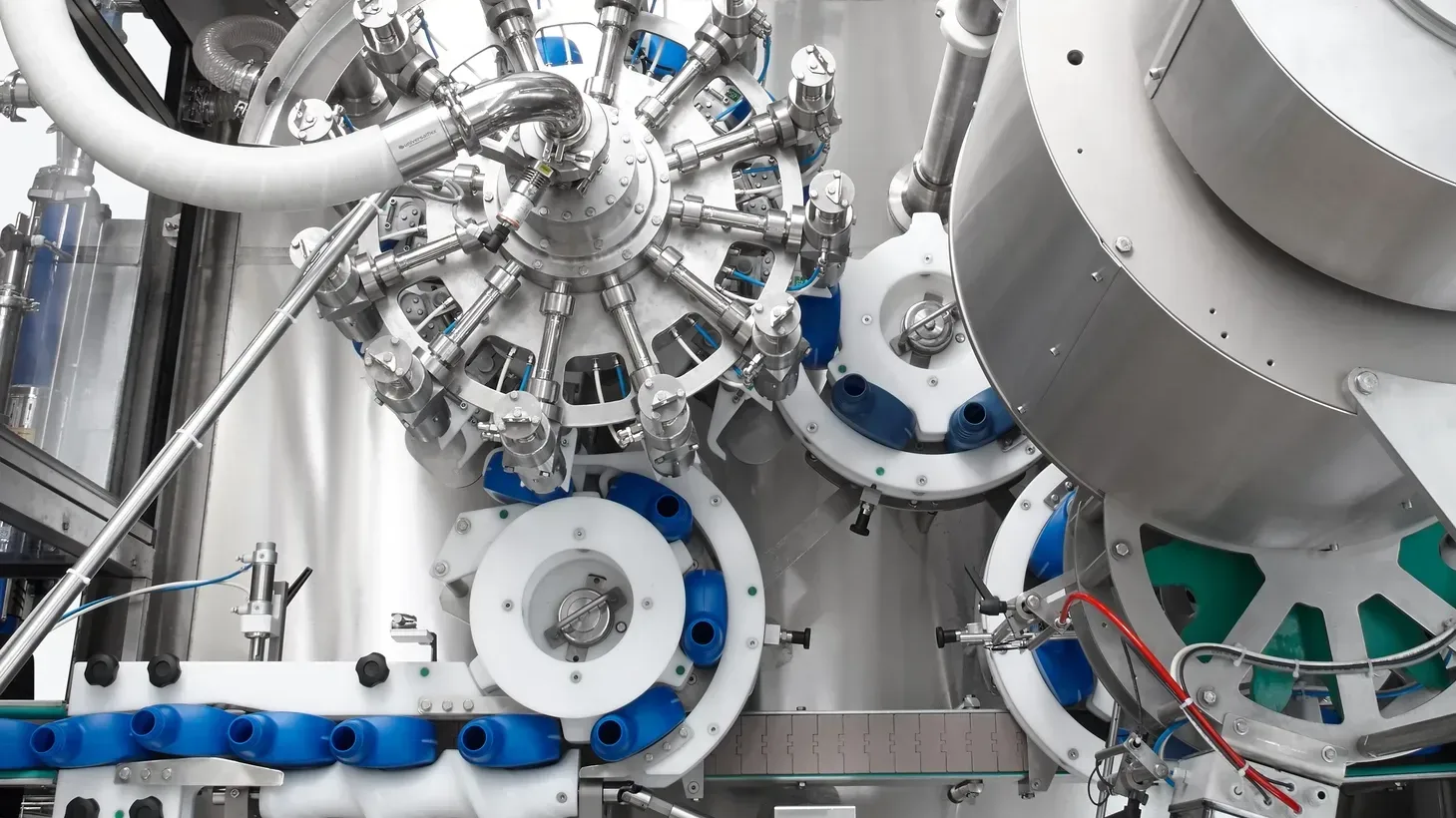

Capping options

Crimped aerosol valve

Flip-top

Oriented press-on

Screw cap