“We have huge customers and we are relatively small. Let's ask why, let's ask why huge companies buy complex machines from us that must last at least 20 years.

There is only one answer: because we are credible.”

Carlo Corniani

The companies we engage with, how we do it and the relationships we reach to establish are a direct and immersive representation of how our corporation is working inside.

Through the voices of our clients and their case studies, we can illustrate and analyze not only the challenges faced and the solutions found, but also the journey undertaken together.

The search for the right solution becomes an opportunity for mutual discovery and growth.

In every story there is an encounter, a dialogue between need and solution, an embrace between challenge and resolution, where our experience merges with external vision and expectation, creating a unique harmony of shared success.

SI.STE.M., is a benchmark reality in the field of laundry and soap detergents.

The company fabricates softeners and degreasers, including the world renowned Chanteclair brand and relies on Weightpack machines for their Sant’Agata Bolognese product packaging operations.

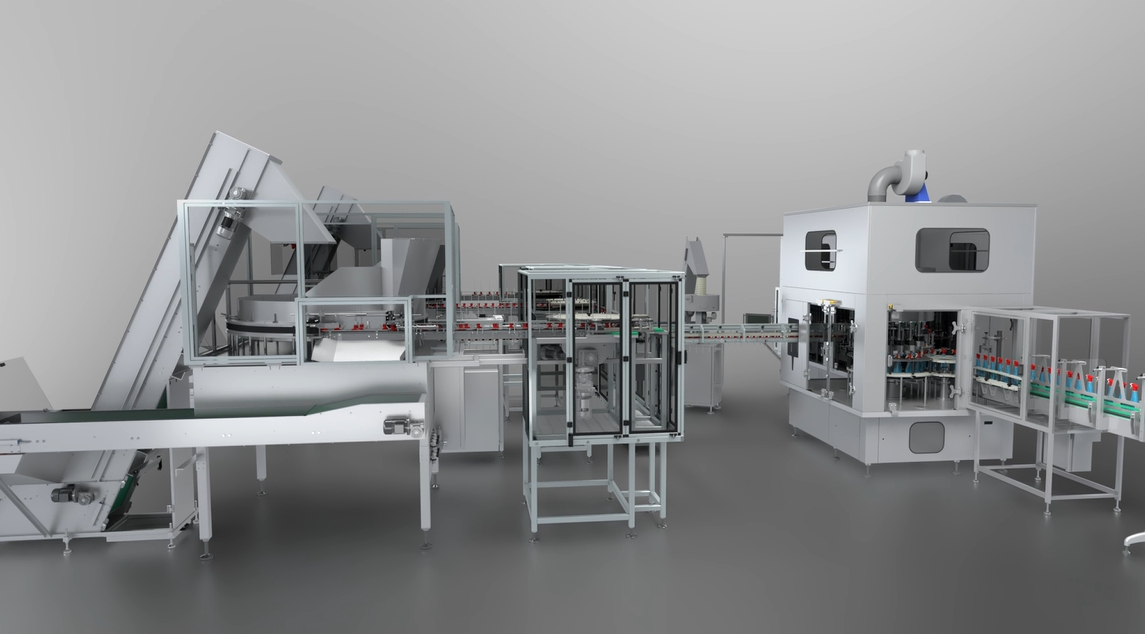

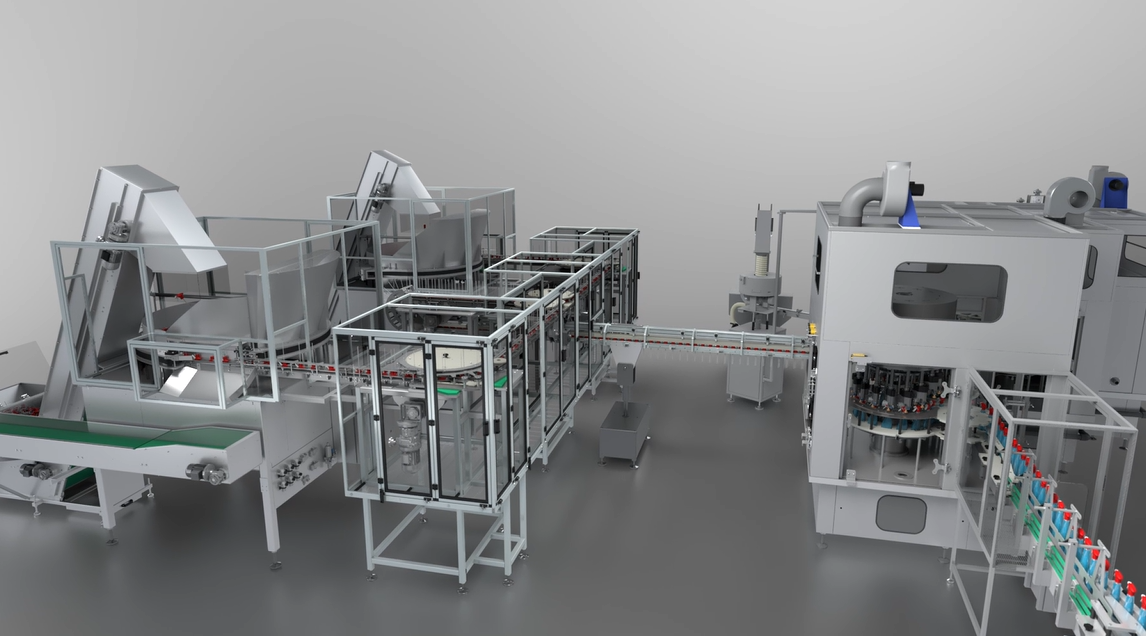

Twin Cap Sorter is the name of the newest proposal from Weightpack, presented at the Interpack fair in Düsseldorf in 2023 To meet the exploding demand for household cleaning products the Italian company has developed an efficient and practical solution for doubling the speed of its machinery: this trigger cap feeder can in fact process more than 330 spray closures per minute. That’s nearly twice as fast as the company’s standard machinery, on a small footprint and at sustained speed.

The machine features a structure true to its name: two "twin" sorters, working simultaneously and in an independent way to distribute the triggers and unscramble them, make them marching toward the capping machinery. This allows great versatility and represents a huge advantage in terms of production. Redundancy means that should one sorter fail temporarily, the twin component will continue serving up trigger sprayers. Nonstop production, because performance comes first!

Not only that, but the twin version also allows the operator to have greater and easier accessibility, thanks to the strategically placed doors facing outward and thanks to the internal space that is created between the two sorters.

Client SI.STE.M.

Machine Anticorrosion

Application Home Care

Final product Household cleaner

Net weight filling

Net content 750 ml

Base / Neck handling Base handling

Filling heads 50

Filling valves Pneumatic piston / Pneumatic-magnetic / Solenoid / Multistage

Filling precision σ < 1g

Filling pitch 113 mm

Speed 18.000 BPH

Product delivery Tank on board / Tankless

Capping

Capping option Spray triggers (patented non-slip torqueing heads)

Capping heads 16

Rotary Clockwise

Refill capping heads (trigger only) 15

Capping pitch 141 mm

Sorter Centrifugal